Your Digital Twin:

VR and AR Platform

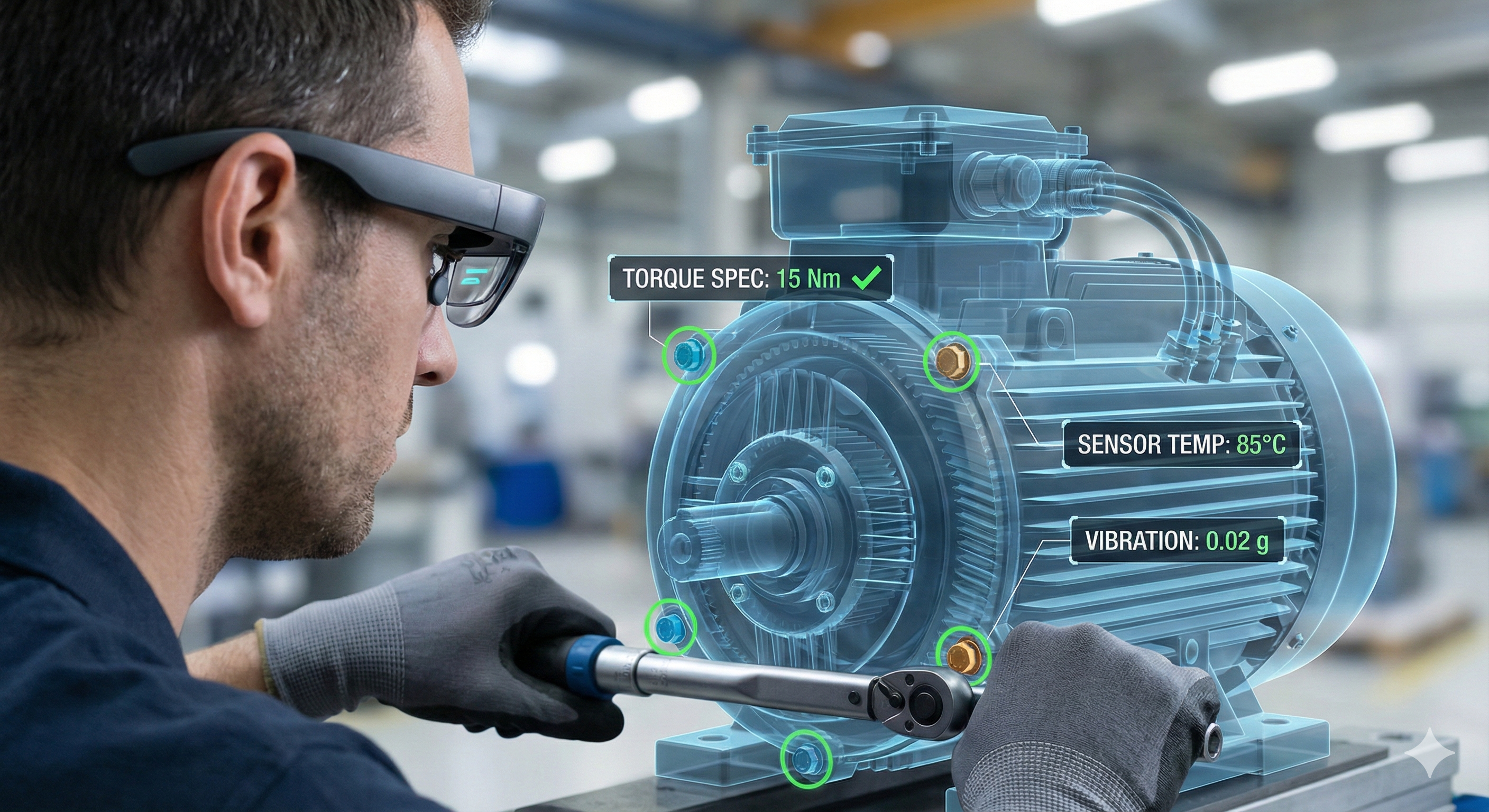

Use VR for immersive design reviews, remote collaboration and hands-on training, while AR overlays live instructions and machine states directly on the real asset so teams learn faster, make fewer mistakes, and execute complex work with confidence.

Use Cases

Assembly & Maintenance Instructions

AR overlays show technicians exactly where/how to assemble equipment.

Remote Inspection & Expert Assist

Technicians share AR views with remote experts in real-time.

Onboarding & Skills Training

Use VR to train new hires. Increase productivity, fewer errors.

Design & Process Reviews

Walk through a NEW production line in immersive VR before building it.

Knowledge Capture

Record retiring experts.

Compliance & Safety

Audit-ready VR drills.

How It Works

Digital Twin Genesis

Ingest CAD files, 3D scans, and BIM models. We bind them to live telemetry (PLC, RPM, Temp) to create a living twin.

Scene Logic & Auth

Inject interactivity. Add hotspots, training scenarios, and 'If/Then' failure conditions without writing code.

Virtual Immersion (VR)

Launch multi-user sessions. New hires and experts collaborate in the same virtual lobby, regardless of physical distance.

Reality Overlay (AR)

Push to mobile/glasses. The Digital Twin snaps onto physical equipment, giving technicians x-ray vision for torque specs and sensors.

SYSTEM ARCHITECTURE

Modular capabilities for the connected workforce.

Problem

Design flaws caught on floor = expensive rework.

Solution

Walk 3D layouts in VR before equipment arrives.

Benefit

Catch problems in 2 hours vs. 2 weeks.

Engineered for Impact

Every component of lavrour is designed with one principle: enable plant managers to see, understand, and resolve manufacturing issues faster than ever before. From AI to architecture, from latency to security, we've obsessed over every detail.

Vision Transformers & Neural Networks

Advanced deep learning models process visual factory data in real-time. Our proprietary AI trains on 50+ data types including temperature, vibration, sound, and optical sensors to identify anomalies before they become incidents.

Latency Matters

In manufacturing, every millisecond counts. Our edge-deployed AI processes data with<20ms latency, enabling real-time collaboration and instant decision-making.

Enterprise Security

Built for compliance. All data stays within your infrastructure with edge compute deployment. SOC 2 Type II certified. HIPAA, GDPR, and IEC 62443 ready.

Multi-User VR Collaboration

Up to 20 users see the same 3D factory environment simultaneously. Regional VP in Berlin and plant manager in Mexico City can point at the same machine, draw annotations in 3D space, and solve problems together with integrated voice comms.

Integrate with Existing Systems

Plug into Siemens, AWS IoT, PTC ThingWorx, or custom MQTT. No rip-and-replace. No ETL pipelines. lavrour becomes the visualization layer on top of your existing manufacturing stack.

Onboard in 30 Days

Week 1: Connect your data. Week 2: Configure VR environment. Week 3: Train your team. Week 4: Go live. No custom development required. No 6-month IT projects.

Built on Real Code

lavrour isn't a dashboard wrapped in a dashboard. It's a real-time intelligence engine built on production-grade infrastructure. Below is a simplified representation of our factory analysis pipeline—the same code running 24/7 across thousands of facilities.

Real-Time Analysis

Our engine processes data from 50+ sensor types simultaneously. Machine learning models identify patterns invisible to human operators. Results are delivered in milliseconds, not minutes.

Context Matters

We don't just flag anomalies. We understand context. Historical patterns, maintenance schedules, production targets, and seasonal variations all inform the analysis. This is why our AI achieves 72% accuracy out of the box.

Human-Readable Output

The AI doesn't dump raw data. It explains itself. Severity levels, root cause analysis, and recommended actions arrive in natural language through your VR interface or mobile app.

TECHNOLOGY STACK

Simple, Transparent Pricing

No hidden fees. No surprise AWS bills. Everything is included in your monthly subscription. Enterprise customers see ROI within 7 days.

Starter

Perfect for single facility pilots

Growth

For multi-facility operations

Enterprise

For global manufacturing groups

Frequently Asked Questions

Do you offer discounts for annual billing?+

Yes. Annual plans receive 20% discount. Annual billing also includes priority support and early access to new features.

Can we change tiers mid-cycle?+

Absolutely. Upgrade or downgrade anytime. We'll prorate your bill accordingly. No penalties.

What if we exceed our machine limit?+

We scale with you. Add machines anytime at $50/machine/month. No minimum commitment.

Is there a setup fee?+

Implementation costs are separate ($25K one-time). This includes data connection, VR environment configuration, and team training.

Do you offer a free trial?+

Yes. 30-day free trial with your real data. Full access to platform. No credit card required to start.